Landfill and environmental protection projects require a high level of reliability, as any failure in the containment system may result in serious environmental and regulatory consequences. Modern landfill engineering relies heavily on geosynthetics, particularly geomembranes and geotextiles, to form effective barrier and protection systems.

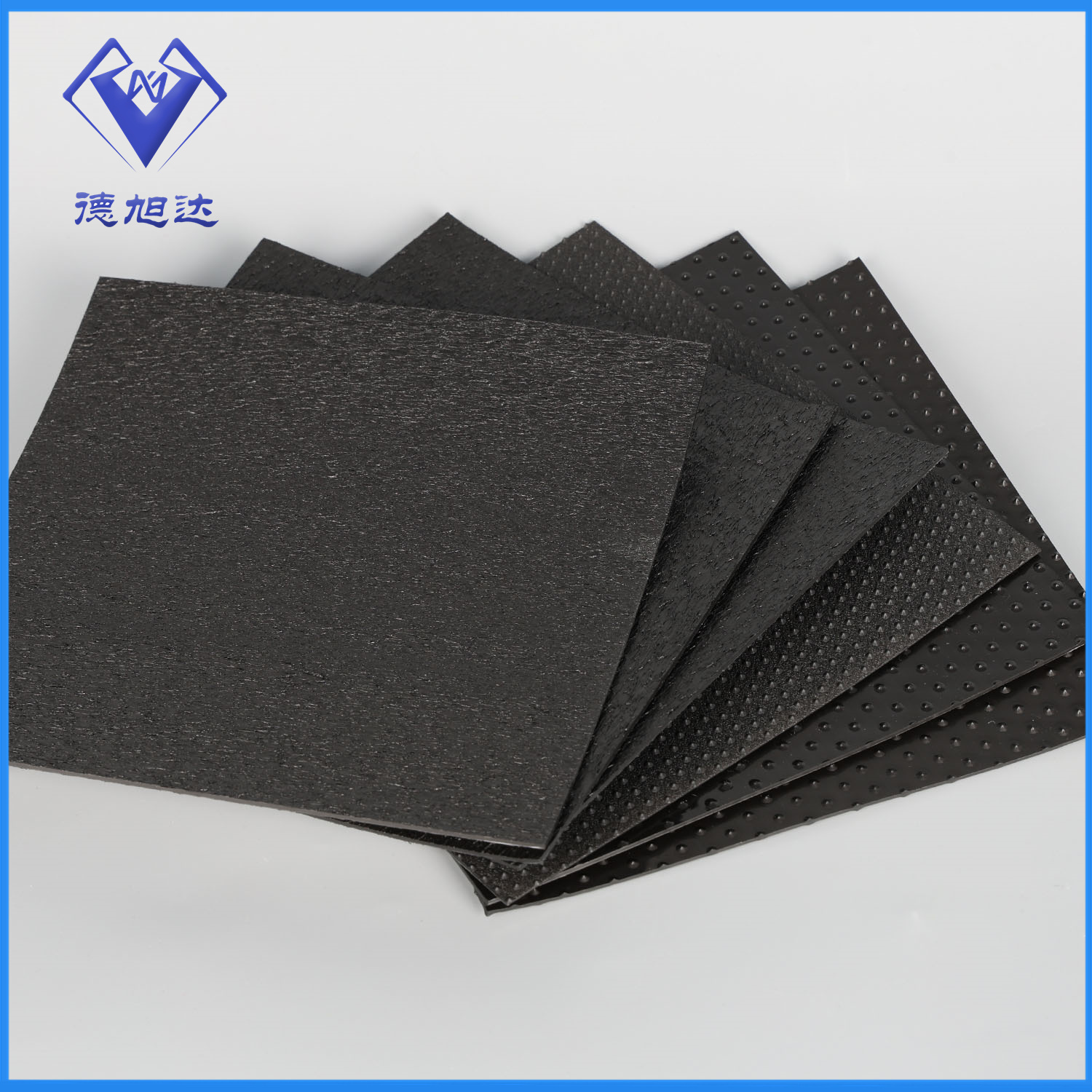

Geomembranes serve as the primary impermeable barrier in landfill liner systems. Their main function is to prevent leachate generated from waste decomposition from migrating into surrounding soil and groundwater. HDPE geomembranes are widely used due to their excellent chemical resistance, low permeability, and long-term durability under continuous exposure to aggressive liquids.

In a typical landfill system, geomembranes are installed as primary liners, secondary liners, and cover systems, depending on project design. Thickness selection is based on factors such as waste type, expected load, and service life requirements. Consistent thickness and stable mechanical properties are critical to avoid weak points that could lead to leakage.

Geotextiles play a vital supporting role in landfill applications. Non-woven geotextiles are commonly used as cushioning and protection layers, placed above and below geomembranes. Their function is to reduce puncture risk caused by sharp aggregates, uneven subgrade, or construction activities. By distributing stress more evenly, geotextiles help extend the service life of the geomembrane.

In addition, geotextiles are widely applied in filtration and drainage layers, allowing leachate and gas to flow while preventing soil particle migration. Proper filtration performance is essential to avoid clogging, which could compromise drainage efficiency and increase pressure on the liner system.

Environmental protection projects often require materials that can perform reliably for decades. Therefore, quality control and material selection are critical. Our geomembranes and geotextiles are manufactured under strict quality management systems, with routine testing for tensile strength, elongation, puncture resistance, permeability, and mass per unit area.

From a practical perspective, landfill projects are usually large-scale and require significant material volumes. We offer customized roll sizes and packaging solutions to improve transportation efficiency and reduce on-site handling time. Our experience in exporting to developing markets ensures that materials arrive in good condition and are suitable for local installation practices.

By combining high-quality geomembranes with properly selected geotextiles, landfill operators can achieve a reliable, long-lasting containment system that meets environmental regulations while controlling construction and maintenance costs.